Manufacturer of Portable Hydraulic Testing Instruments

HIGHLAND MYHT SERIES

Portable hydraulic test equipment for measuring flow, pressure and temperature within a hydraulic system

Products Advantages

MYHT Digital Portable Hydraulic Tester offers accurate and efficient testing of hydraulic systems. Its user-friendly interface and compact design make it easy to use on the go. Get fast, precise results with this advanced hydraulic tester.

Application Fields

Product Specifications

|

Model |

Max flow(lpm) |

Max presure(bar) |

Dimension(mm) |

Weight(kg) |

|

MYHT—1—2 |

200 |

420 |

295×265×210 |

6.1 |

|

MYHT—1—4 |

400 |

420 |

295×265×210 |

8.8 |

|

MYHT—1—5 |

500 |

420 |

295×265×210 |

10.2 |

|

MYHT—1—7 |

800 |

420 |

310×285×261 |

14 |

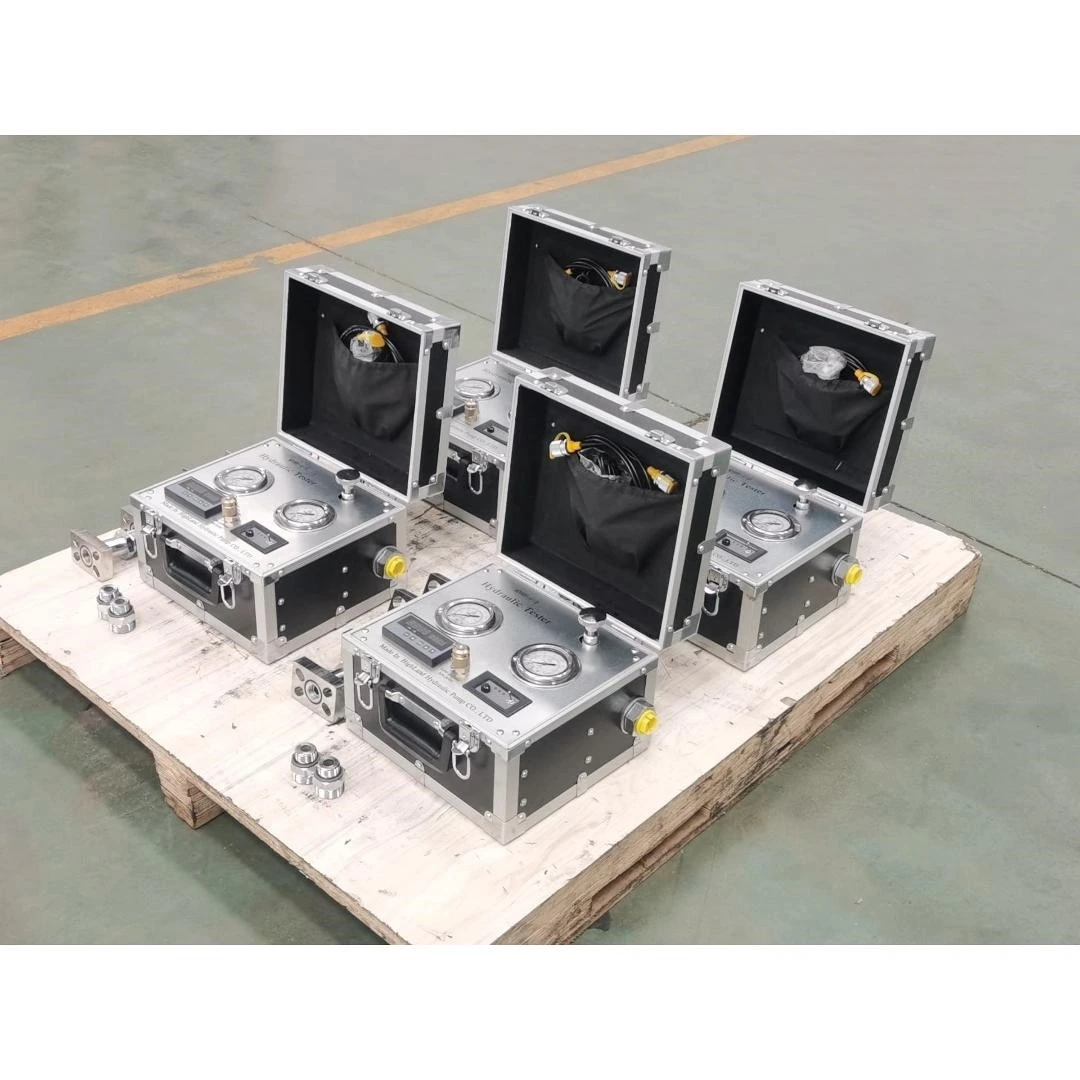

MYHT series portable hydraulic tester

Portable hydraulic tester is suitable for on-site diagnosis and measurement of hydraulic system flow, pressure, and temperature in construction equipment!

Core Product

The Portable Hydraulic Tester is an advanced diagnostic tool that combines high-precision measurement, rugged construction, and a user-friendly interface. Designed for field engineers, maintenance technicians, and mechanics, it enables quick and accurate assessment of a hydraulic system's core health with minimal system intrusion or downtime.

Key Features

Mobile & Portable: Housed in a rugged, protective case that integrates all core components and accessories. It is fully portable and can be moved to any site—workshop, field, or elevated platform. Ready for immediate response to unexpected breakdowns.

Complete Kit, Ready-to-Use: This kit is an integrated solution combining a flow and pressure tester with a comprehensive hydraulic analyzer. It comes as a complete kit with all essential accessories, including multiple quick-connect couplers, high-pressure hoses, temperature sensors, data cables, and professional analysis software. Compatible with most hydraulic equipment, it offers "one-device, full-system diagnostics."

Troubleshooting Solution

Abnormal System Pressure:

Problem: Unstable pressure, failure to build high pressure, or excessive pressure.

Solution: Monitor real-time pressure profiles at key points (pump outlet, valve block, actuator inlet). Precisely identify whether issues stem from pump wear, faulty relief/pressure reducing valves, or cylinder leakage.

Overheating Diagnosis:

Problem: Abnormal hydraulic oil temperature rise.

Solution: Monitor system temperature and, by measuring overall flow and pressure drops, calculate system power loss. Pinpoint if the cause is a faulty cooler, excessive internal leakage (low efficiency), or a stuck relief valve wasting energy.

Why Choose Our Solution

Fast ROI: Reduce troubleshooting time by up to 70%, prevent costly part replacement errors, and extend equipment life.

Enhance Reliability: Shift from reactive repair to proactive prevention, ensuring production continuity and equipment availability.

Knowledge Empowerment: Replace guesswork with data, elevating your maintenance team's technical capability and decision-making.

Packing & Delivery

To protect the goods, we pack and fix goods at least two layers. The first layer is plastic bag to protect against moisture, the second is to fix hydrostatic pump in the plywood case because its heavy goods, the third is plywood case, standard export package.

FAQ

ADD:No. 2 Tianchen Road, Yucheng High-tech Zone, Shandong

Copyright © www.highlandhydrostatic.com | Sitemap | Privacy Policy