How Hydraulic Piston Motors Work: A Step-by-Step Guide

Hydraulic piston motors are the unsung heroes of modern machinery, transforming hydraulic fluid into mechanical energy with incredible efficiency. These motors are integral to a wide range of applications, from construction equipment to industrial machinery. Understanding how they work and their various applications can greatly enhance their performance and longevity.

Understanding Hydraulic Piston Motors

Hydraulic piston motors are designed to convert hydraulic energy into mechanical energy, providing the power needed for heavy-duty operations. They are versatile, reliable, and can handle a variety of tasks with precision and efficiency.

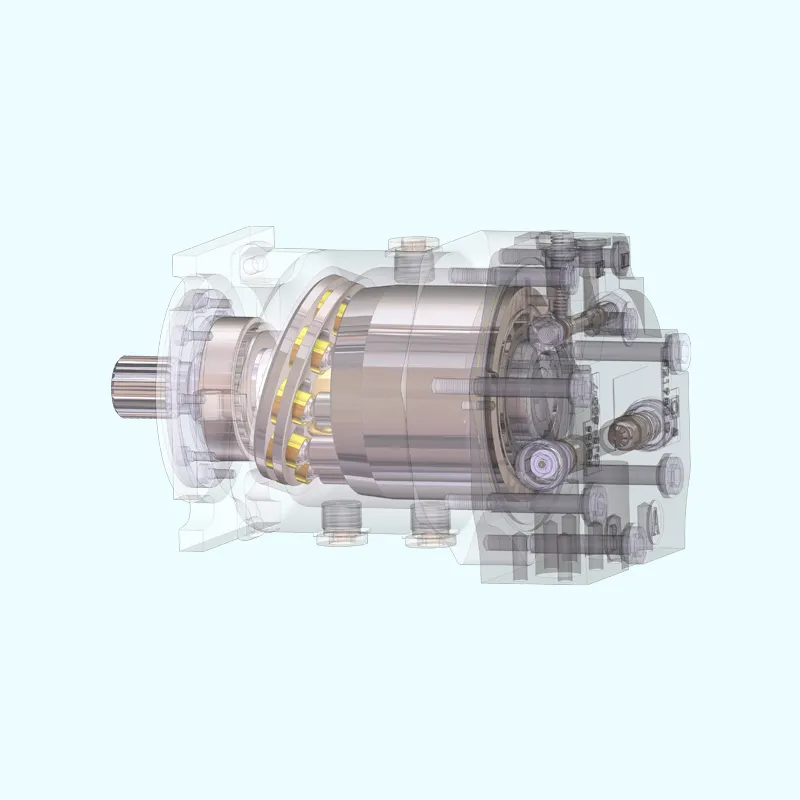

The core of a hydraulic piston motor includes:

- Cylinder: Enclosed by a housing, this metallic tube houses the piston and creates the sealed environment for the hydraulic fluid.

- Piston: A moveable part that reciprocates within the cylinder, converting hydraulic fluid pressure into mechanical force.

- Connecting Rod: Links the piston to the output shaft, transmitting the motor's motion to the machinery it powers.

- Hydraulic Oil: A pressurized fluid that flows through the motor, interacting with the piston and connecting rod to produce motion.

- Pump: Supplies the hydraulic fluid to the motor, maintaining the necessary pressure.

The high torque generated by hydraulic piston motors makes them ideal for applications requiring significant power and precision, such as lifting, pressing, and compressing materials.

The Fundamentals of Hydraulic Piston Motors

Hydraulic piston motors come in several types, each with its unique features and applications. The two main types are radial piston motors and axial piston motors. Additionally, there are volumetric piston motors, which have their own advantages.

Radial Piston Motors

Radial piston motors have pistons arranged radially around a central axis. This design is compact and efficient, making it ideal for small-scale machinery and mobile equipment. They are known for their high torque output and precision.

Axial Piston Motors

Axial piston motors have pistons arranged along the axis, providing high power output and durability. They are commonly used in construction machinery, heavy-duty machinery, and industrial equipment.

Volumetric Piston Motors

Volumetric piston motors use a volumetric pump to supply hydraulic fluid, providing more efficient operation and reducing pressure fluctuations. They are used in applications where precise control is necessary, such as machine tools and precision machinery.

The Working Principle of Hydraulic Piston Motors

Hydraulic piston motors work based on the principle of converting hydraulic energy into mechanical energy. Heres how it happens step-by-step:

1. Filling Phase: Hydraulic fluid is pressurized and flows into the cylinder, creating a vacuum that pushes the piston outward.

2. Closing Phase: The piston moves outward, compressing the hydraulic fluid and creating a seal around the cylinder walls.

3. Repeating Phase: The piston moves inward, allowing the hydraulic fluid to flow back into the pump and maintaining the pressure required for the next cycle.

4. Closing Phase: The piston returns inward, completing the cycle and repeating the process.

This cyclical operation ensures continuous motion, which is transmitted to the output shaft via the connecting rod.

Types of Hydraulic Piston Motors

1 Radial Piston Motors

Radial piston motors are compact and efficient, making them ideal for small-scale machinery and mobile equipment. They are particularly effective in applications requiring high torque and precision.

2 Axial Piston Motors

Axial piston motors are known for their high power output and durability. They are commonly used in construction machinery, heavy-duty machinery, and industrial equipment. They can handle large volumes of hydraulic fluid and provide excellent force.

3 Volumetric Piston Motors

Volumetric piston motors use a volumetric pump to supply hydraulic fluid, offering more efficient operation and reduced pressure fluctuations. They are essential in applications where precise control is required, such as machine tools and precision machinery.

Applications of Hydraulic Piston Motors

Hydraulic piston motors are used in a variety of applications, including:

Construction Equipment

In construction, hydraulic piston motors are used in machinery such as excavators, bulldozers, and dump trucks. They provide the power needed to lift and lower heavy equipment and operate hydraulic cylinders.

Industrial Machinery

In manufacturing, mining, and automotive industries, hydraulic piston motors drive machinery such as compressors, pumps, and machine tools. They ensure high torque and precision, making them essential for efficient operations.

Marine Vessels

In marine applications, hydraulic piston motors are used in cranes, hoists, and machinery on board ships and yachts. They provide the power needed to operate heavy machinery and equipment on board.

Agriculture

In agriculture, hydraulic piston motors power machinery such as tractors, harvesters, and irrigation systems. They handle heavy-duty operations with precision and efficiency.

Maintenance and Troubleshooting of Hydraulic Piston Motors

Maintaining hydraulic piston motors is crucial for optimal performance and longevity. Regular maintenance includes:

- Hydraulic Fluid Check: Ensure the fluid is clean and at the correct pressure. Replace if necessary.

- Piston Check: Inspect for wear or damage. Replace if worn.

- Connecting Rod Check: Inspect for wear or damage. Replace if damaged.

- Pump Check: Inspect for wear or damage. Replace if necessary.

- Filter Check: Ensure the filter is clean and properly seated. Replace if necessary.

Troubleshooting common issues such as leaks, low pressure, or reduced performance involves checking the hydraulic fluid, pumps, pistons, and connecting rods.

Real-World Application of Hydraulic Piston Motors

A real-world example of hydraulic piston motors in action is in construction machinery, such as excavators. Excavators use hydraulic piston motors to lift and lower heavy equipment and operate hydraulic cylinders.

In an excavator, the hydraulic piston motor is connected to a hydraulically operated bucket, boom, and cab. The motor drives the output shaft, which powers the boom and cab. The motor's high torque and precision ensure efficient and safe operation.

The high torque and reliability of hydraulic piston motors make them ideal for construction machinery. They handle heavy loads with ease and provide the power needed for lifting and moving equipment.

Conclusion

Hydraulic piston motors are essential components in many mechanical systems, from construction equipment to industrial machinery. Their ability to convert hydraulic energy into mechanical energy with high efficiency makes them popular in industries that require precision and power. By understanding their working principles and applications, you can ensure that these motors operate efficiently and for a long time.

To summarize, hydraulic piston motors are versatile, reliable, and capable of handling heavy-duty operations with precision. Whether you're working in construction, manufacturing, or any industry that relies on heavy machinery, understanding these motors can greatly enhance your productivity and efficiency.

-

-

-

-

5.4Agriculture

ADD:No. 2 Tianchen Road, Yucheng High-tech Zone, Shandong

Copyright © www.highlandhydrostatic.com | Sitemap | Privacy Policy