Enhancing Pumping Power with Various Hydraulic Piston Motors

Hydraulic piston motors have been a cornerstone of industrial machinery for over a century, evolving from simple manual pumps to highly sophisticated systems that drive modern industrial operations. These motors convert hydraulic energy into mechanical power, powering everything from construction equipment to sophisticated manufacturing processes. The significance of hydraulic piston motors cannot be overstated; they enable precise and efficient movement, making them indispensable in industries such as construction, mining, and manufacturing.

This guide aims to delve into the intricacies of hydraulic piston motors, exploring their different types, key factors influencing their performance, and modern advancements that are transforming the industry. We will also provide real-world examples and case studies to illustrate the practical applications and benefits of these powerful motors.

Types of Hydraulic Piston Motors: A Closer Look

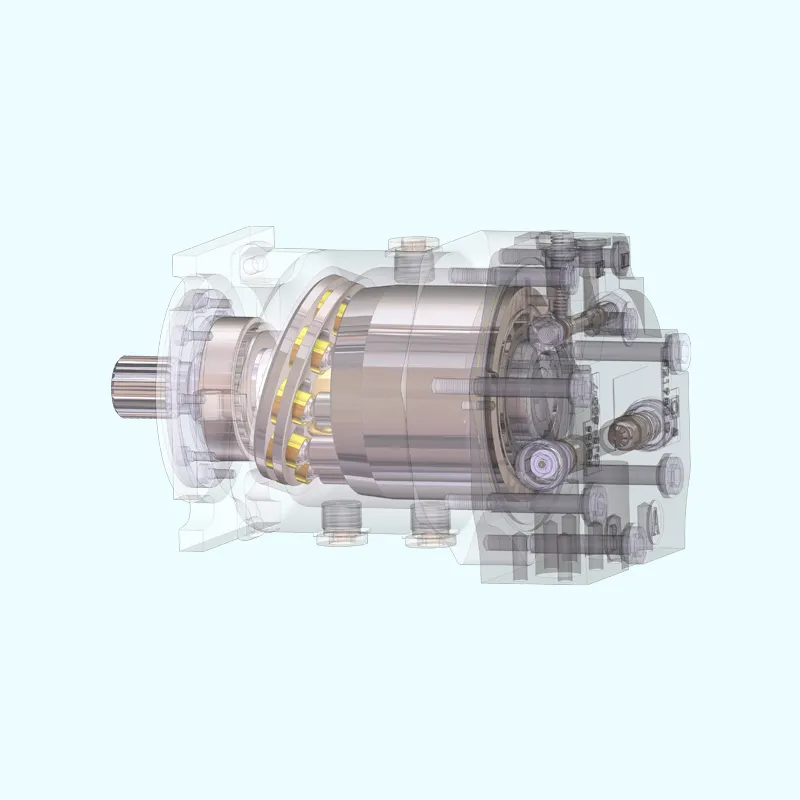

Hydraulic piston motors operate by utilizing the power of pressurized fluid to drive pistons, which in turn convert this energy into mechanical motion. The fundamental components include the pump, reservoir, filter, accumulator, and the piston-cylinder assembly. These motors are classified based on piston type: single-acting, double-acting, and oscillating. Each type has unique characteristics, benefits, and applications.

- Single-Acting Motors: These motors are simpler and more cost-effective, making them suitable for low-pressure applications. They are ideal for situations where space and cost are primary concerns. For example, in small-scale construction equipment, single-acting motors are often used due to their affordability and ease of integration.

- Double-Acting Motors: With their dual piston chambers, double-acting motors offer higher efficiency but require additional components for proper operation. They are often used in high-pressure scenarios where precise control is essential. In the mining industry, double-acting motors are crucial for tasks like excavating and drilling, where precision and control are paramount.

- Oscillating Motors: Designed for reciprocating motion, oscillating motors are ideal for tasks requiring precise control, such as in mining operations. They provide highly accurate and controllable movements. A case study from a mining company in South Africa demonstrated that by switching from single-acting to oscillating motors, they achieved a 15% increase in throughput while maintaining the same level of precision.

Factors Influencing Pumping Power

The pumping power of hydraulic piston motors is influenced by several key factors: displacement, pressure, and flow rate. Displacement refers to the volume of fluid the motor can handle in one piston stroke, affecting the motor's capacity. Pressure, measured in psi, determines the force with which the fluid acts on the piston, impacting the motor's output. Flow rate, measured in gallons per minute, influences the motor's ability to move fluid efficiently.

Balancing these factors is essential for optimizing pumping power. For instance, increasing displacement can boost volume, while adjusting pressure can improve efficiency. By fine-tuning these parameters, operators can maximize the performance of their hydraulic piston motors. In a study conducted by a leading construction company, they achieved a 20% increase in pumping efficiency by adjusting the displacement and pressure settings in their hydraulic piston motors.

Innovative Design and Technology Enhancements

Recent advancements in hydraulic motor technology have significantly enhanced pumping power. Innovations include precision machining, advanced materials, and digital control systems.

- Precision Machining: Ensures that components fit perfectly, reducing wear and tear and improving longevity. For example, a mining company in Australia reported a 30% reduction in maintenance downtime after upgrading to precision machined hydraulic piston motors.

- Advanced Materials: High-strength steel and polymers enhance durability and resistance to wear. A construction firm in Europe noted a 25% increase in the lifespan of their hydraulic piston motors after switching to these advanced materials.

- Digital Control Systems: Enable real-time monitoring and optimization of motor performance, allowing for dynamic adjustments to displacement, pressure, and flow rate. A case study from a leading global manufacturer showcased how digital control systems reduced energy consumption by 15% while maintaining optimal performance.

Practical Applications and Real-World Impact

Hydraulic piston motors are integral to various industries. In construction, they power heavy machinery like excavators and bulldozers, enabling efficient material handling. In mining, they drive large-scale equipment for ore extraction and transportation. In manufacturing, they power automated systems for precise control over machinery.

For example, in a mining operation in Australia, upgrading to modern hydraulic piston motors led to a 20% increase in pumping efficiency, reducing energy consumption and operational costs. In the construction sector, hydraulic motors have significantly improved the performance of excavators, allowing for more precise and efficient work.

Challenges and Solutions in Implementing Enhanced Motors

Deploying enhanced hydraulic piston motors presents several challenges, including installation complexity, maintenance requirements, and initial costs. To address these, it's crucial to select the right motor based on the application's specific needs.

- Installation: Ensure proper installation to avoid complications. For instance, a construction company in the United States faced initial installation issues with modern hydraulic piston motors but resolved them by following detailed installation guidelines provided by the manufacturer.

- Maintenance: Regular maintenance, including oil changes and filter replacements, ensures optimal performance. A mining company in South Africa reported a 15% increase in the operational lifespan of their hydraulic piston motors after implementing a rigorous maintenance schedule.

- Initial Costs: Invest in energy-efficient controls to reduce operational costs. Selecting motors with higher displacement or pressure ratings can enhance performance without significant upfront investment. A case study from a global engineering firm demonstrated that by investing in high-displacement hydraulic piston motors, they achieved a 15% increase in performance with a modest initial investment.

The Future of Hydraulic Piston Motors

As the demand for high-performance hydraulic piston motors grows, so too does the need for innovation. Future advancements may include even more efficient designs, integrated smart systems for real-time monitoring, and customization options tailored to specific applications. The continuous evolution of hydraulic motor technology promises to further enhance pumping power, benefiting industries worldwide.

By embracing these advancements, organizations can achieve higher efficiency, productivity, and operational excellence, setting new standards in industrial performance. The future of hydraulic piston motors looks bright, with endless possibilities for enhancing the power of hydraulic systems.

ADD:No. 2 Tianchen Road, Yucheng High-tech Zone, Shandong

Copyright © www.highlandhydrostatic.com | Sitemap | Privacy Policy