Troubleshooting Guide for Variable Swash Plate Hydraulic Pumps

Introduction to Variable Swash Plate Hydraulic Pumps

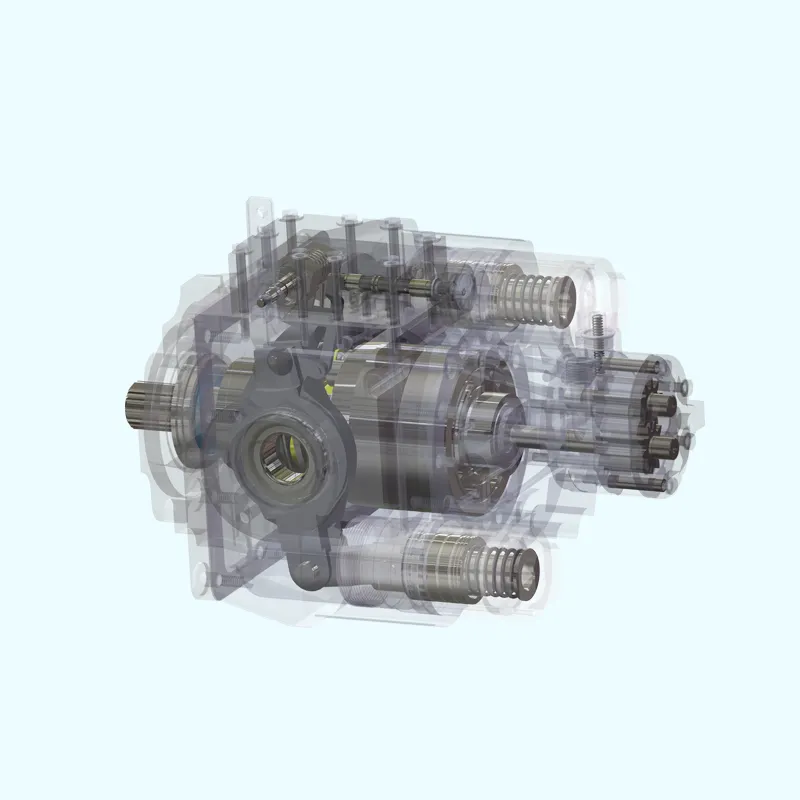

Variable swash plate hydraulic pumps are essential components in various industrial applications, offering adjustable displacement to optimize performance. These pumps use a swash plate, a movable component that adjusts the angle of the pump's intake and outlet ports, thereby controlling the volume of fluid displaced. Unlike fixed displacement pumps, the variable type provides flexibility, making them ideal for systems with varying demand. Understanding their operation is crucial for effective maintenance and trouble shooting.

Common Faults and Symptoms in Variable Swash Plate Pumps

While variable swash plate pumps are robust, they can develop common issues such as noise, overheating, pressure fluctuations, and pump wear. Excessive noise often indicates worn-out components or blocked ports. Overheating can be linked to high discharge temperatures or inefficient cooling systems. Pressure fluctuations might suggest problems with the pump's displacement or the system's load regulation. Pump wear, especially at the bearings or seals, can lead to failure over time, necessitating immediate attention.

Causal Analysis: Diagnostic Tools and Techniques

Diagnosing issues with variable swash plate pumps requires a combination of diagnostic tools. Pressure gauges measure discharge pressure, helping identify overpressure symptoms. Temperature sensors track internal temperatures, indicating potential overheating. Spectroscopic tools analyze oil quality, revealing signs of wear or contamination. Additionally, visual inspections can detect physical damages like port fouling or bearing wear. These tools provide critical insights, guiding the troubleshooting process effectively.

Step-by-Step Troubleshooting Procedures

A systematic troubleshooting approach is vital for resolving issues efficiently. Begin with visual inspections to check for physical damages or blockages. Proceed to functional tests, ensuring the pump operates smoothly under load. If functional tests fail, move to component testing, using pressure, temperature, and spectroscopic tools to diagnose specific issues. This structured method ensures thorough identification and resolution of problems.

Maintenance and Prevention Tips

Proactive maintenance is key to preventing issues with variable swash plate pumps. Regular servicing includes oil changes and filter replacements to maintain optimal performance. Lubrication ensures smooth operation, while monitoring temperature fluctuations helps prevent overheating. Handling pumps with care during operation minimizes wear and tear. Implementing these practices enhances longevity and efficiency, reducing the need for frequent repairs.

Case Studies and Real-World Examples

Real-world examples illustrate the importance of proper troubleshooting. For instance, a pump at an industrial site developed noise issues due to worn ports. A thorough visual inspection revealed fouling, leading to effective cleaning and lubrication, which resolved the problem. Another case involved a pump overheating, traced back to inefficient cooling. Upgrading the cooling system significantly improved performance, demonstrating the effectiveness of proactive measures.

Comparative Analysis of Troubleshooting Solutions

Various troubleshooting methods exist for variable swash plate pumps. Visual inspection is quick but limited in diagnosing internal issues. Pressure and temperature monitoring provide detailed insights but require skilled interpretation. Spectroscopy, though more complex, offers precise analysis of oil quality. Balancing these methods ensures accurate diagnosis and efficient resolution, highlighting the importance of a multi-faceted approach.

Effective Troubleshooting and Maintenance

In conclusion, effective troubleshooting and maintenance are crucial for managing variable swash plate hydraulic pumps. By understanding common issues, utilizing diagnostic tools, and following a systematic approach, the likelihood of successful resolution is enhanced. Emphasizing proactive maintenance and regular checks ensures optimal performance, minimizing downtime and extending pump lifespan. This comprehensive guide empowers users to tackle challenges confidently, ensuring reliable and efficient hydraulic systems.

ADD:No. 2 Tianchen Road, Yucheng High-tech Zone, Shandong

Copyright © www.highlandhydrostatic.com | Sitemap | Privacy Policy