The Role of Variable Piston Pumps in Precision Engineering Processes

Variable piston pumps have become indispensable in modern precision engineering, playing a pivotal role in a variety of industries ranging from semiconductor manufacturing to aerospace and automotive. These pumps are renowned for their unparalleled reliability and adaptability, ensuring precise control and efficient operation where consistent performance is critical. For instance, in the aerospace industry, variable piston pumps are essential for managing complex hydraulic systems, ensuring the safe and efficient functioning of aircraft components. Similarly, in automotive manufacturing, these pumps are crucial in advanced fluid management systems that enhance performance and safety. The precision and reliability of variable piston pumps make them a trusted solution for industries where even the smallest deviations can have significant consequences.

Understanding the Mechanism of Variable Piston Pumps

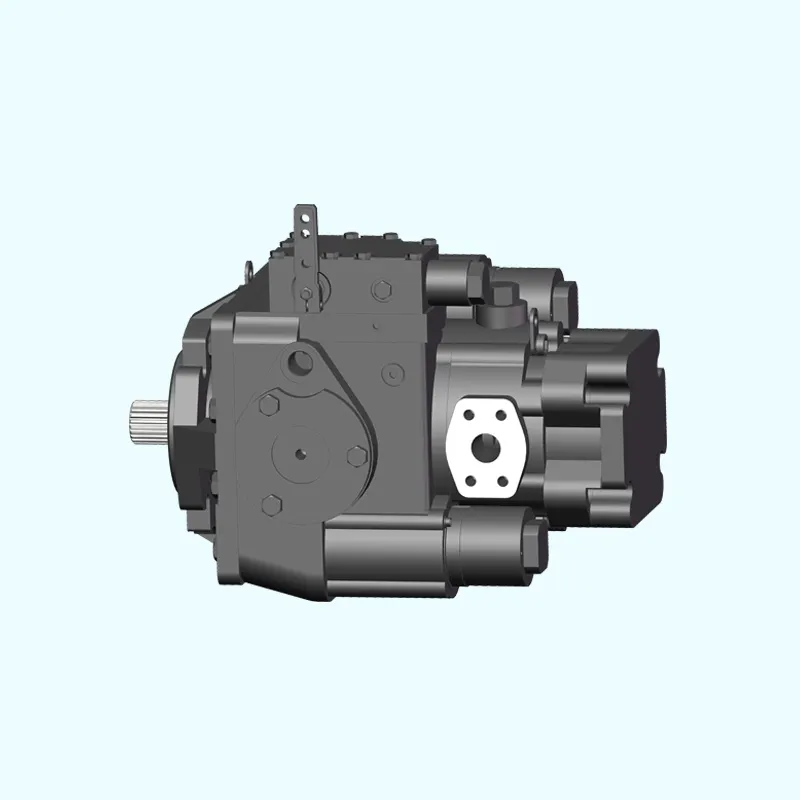

Variable piston pumps operate on a principle that allows them to adjust their displacement, providing dynamic flow control. Unlike fixed displacement pumps, which maintain a constant flow rate, variable piston pumps can vary their output to meet changing demands. This feature is crucial in applications requiring fine control over fluid dynamics, such as in CNC machining and semiconductor manufacturing.

A typical variable piston pump system includes a piston that moves in and out of the cylinder, driving fluid through the displacement mechanism. By adjusting the angle of the cylinder, the displacement can be changed, thereby controlling the flow rate. This design ensures precise control over fluid flow, making variable piston pumps ideal for intricate processes. The pumps internal components, including the piston assembly and control mechanisms, are meticulously designed to minimize leakage and maximize energy efficiency.

Unlike fixed displacement pumps, which often require separate control systems to manage flow rates, and gear pumps, which can be noisy and inefficient, variable piston pumps offer superior energy efficiency and quieter operation. This efficiency and adaptability make them the preferred choice in many industrial settings. Additionally, variable piston pumps can handle a wide range of pressures and flows, enhancing their versatility in both high-pressure and low-flow scenarios.

Precision Engineering Applications of Variable Piston Pumps

The applications of variable piston pumps are vast and varied, each tailored to meet specific operational needs. In semiconductor manufacturing, these pumps are crucial for maintaining ultra-pure water systems, where even minute impurities can render processes ineffective. Their ability to maintain consistent flow rates is essential in such delicate operations, ensuring the purity of water used in critical steps of the manufacturing process.

Similarly, in CNC machining, variable piston pumps supply the precise amounts of coolant and cutting fluids needed to maintain high surface finish and tool wear rates. The pumps reliability and efficiency ensure optimal performance under varying machining conditions, contributing to the high-quality finish and longevity of the tools.

Beyond these industries, variable piston pumps play a vital role in oil and gas exploration, hydrazine production, and pharmaceutical manufacturing. For example, in hydrazine production, the pumps manage the precise transfer of the hazardous chemical, ensuring safe and efficient operations. In pharmaceutical manufacturing, they are used for high-precision dosing systems, ensuring that medications are prepared with utmost accuracy. These critical applications highlight the diverse and essential role of variable piston pumps in precision engineering.

Customization and Tailoring of Variable Piston Pumps

One of the greatest strengths of variable piston pumps lies in their customization. Engineers can tailor these pumps to meet specific industrial requirements, enhancing their functionality and efficiency. Custom designs often involve altering the pumps internal structure, such as modifying the piston rod arrangement or optimizing intake and exhaust ports, to improve flow dynamics. Advanced control systems, such as real-time monitoring and predictive analytics, enable the use of automation software, simplifying monitoring and maintenance.

For instance, in a semiconductor manufacturer, the need for a variable piston pump that can operate at extremely high pressures and maintain precise flow rates over extended periods is crucial. Custom software integration allows the pump to adjust its displacement based on real-time feedback, ensuring optimal performance. Similarly, additive manufacturing techniques can be used to create customized pump parts, further enhancing the pumps adaptability.

Challenges and Solutions in Utilizing Variable Piston Pumps

Despite their many advantages, variable piston pumps do face some challenges. One common issue is wear and tear on the pumps internal components, particularly under high-pressure or heavy-duty conditions. To mitigate this, regular maintenance and the use of high-quality materials are essential. Another challenge is the potential for noise, which can be mitigated through the selection of appropriate sealing technologies and motor types. Energy efficiency is another concern, but advancements in pump design and control systems have addressed these issues.

Proactive measures such as implementing regular maintenance schedules and the use of predictive maintenance technologies can significantly reduce wear and tear. Predictive maintenance algorithms can detect potential issues before they become critical, allowing for timely repairs and extended pump lifespan. For instance, by using sensors to monitor the condition of internal components, engineers can proactively address wear and tear before it leads to system failure.

Future Trends and Innovations in Variable Piston Pumps

Looking ahead, the future of variable piston pumps is poised for significant advancements. Research is ongoing into materials with superior durability and efficiency, aiming to reduce maintenance and operational costs. Electromagnetic drive technologies are being explored to enhance pump performance and reduce carbon footprint. The integration of artificial intelligence and machine learning is expected to further improve pump optimization, enabling smarter control systems that adapt to changing conditions.

Additionally, the development of compact and modular pump designs will facilitate easier installation and upgrading in existing facilities. For instance, integrating AI-driven pump control systems with compact, modular designs can create highly efficient and flexible pump solutions. These advancements will not only enhance the functionality of variable piston pumps but also expand their applicability into new industries, solidifying their role as indispensable tools in precision engineering.

Conclusion

Variable piston pumps play a pivotal role in precision engineering, offering unmatched reliability and adaptability across a spectrum of applications. From semiconductor manufacturing to aerospace and automotive industries, these pumps are indispensable due to their ability to meet the precise demands of modern processes. As technology continues to evolve, variable piston pumps will continue to advance, driving further improvements in precision engineering. By embracing customization, addressing challenges, and investing in future innovations, engineers can unlock the full potential of these pumps, driving advancements in precision engineering for years to come.

ADD:No. 2 Tianchen Road, Yucheng High-tech Zone, Shandong

Copyright © www.highlandhydrostatic.com | Sitemap | Privacy Policy