Swash Plate Piston Pumps vs. Other Pump Types: Which is Best?

Introduction

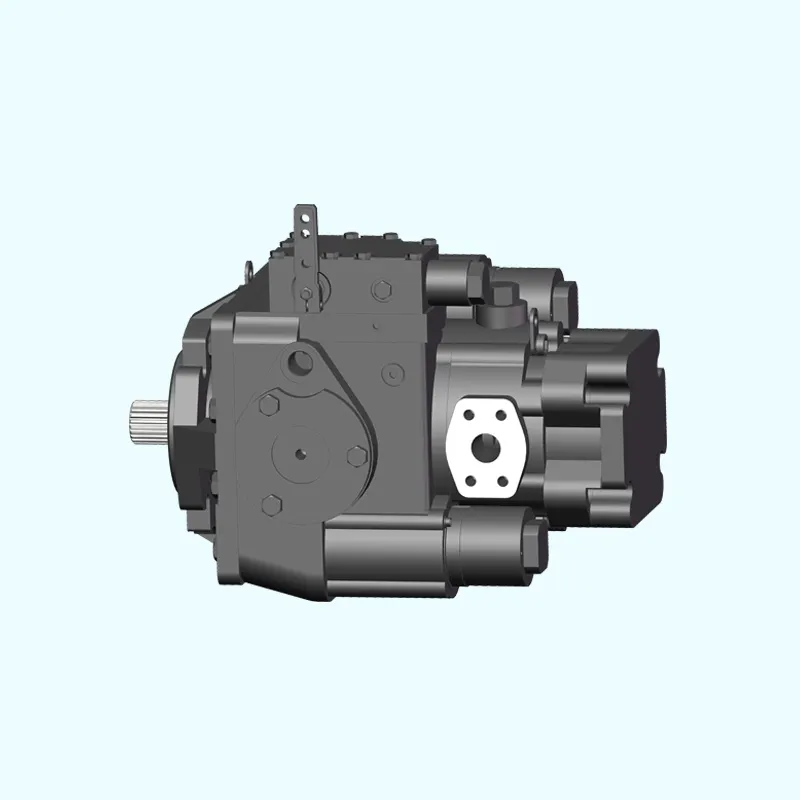

Understanding Swash Plate Piston Pumps

Swash plate piston pumps are a class of positive displacement pumps renowned for their high volumetric efficiency and modular design. These pumps feature a rotating swash plate, which creates a reciprocating motion, displacing fluids with each revolution. Unlike centrifugal pumps, which rely on pressure to move fluids, swash plate pumps use a mechanical reciprocation mechanism, offering quieter and more efficient operation, especially in demanding environments.

The swash plate's design allows for variable displacement, making these pumps adaptable to varying flow requirements. They are widely used in oil and gas, water treatment, and even food processing industries due to their durability and reliability. However, their operation can be less efficient than centrifugal pumps in high-pressure applications, with typical head capacities ranging from 20 to 100 meters.

Comparative Analysis with Other Pump Types

Centrifugal Pumps

Centrifugal pumps are known for their ability to handle high-pressure applications efficiently. They use centrifugal force to accelerate fluid particles, imparting energy to them as they move towards the outlet. While they are compact and adaptable to various fluid types, their efficiency peaks at higher flows and lower heads. Centrifugal pumps are often noisier than swash plate pumps, with higher maintenance requirements, making them less suitable for demanding environments where noise control and low vibration are critical.

Gear Pumps

Gear pumps, with their epicyclic or internal combustion mechanisms, offer a quieter operation compared to centrifugal pumps. They are ideal for viscous fluids and are commonly used in industrial settings where noise reduction is paramount. However, gear pumps typically have lower volumetric efficiency and higher wear rates, necessitating more frequent maintenance and higher initial costs. Their fixed displacement nature limits flexibility in fluid flow adjustment.

Performance Metrics: Efficiency and Reliability

Swash plate piston pumps excel in reliability, with a proven track record in harsh environments. Their modular design enhances maintenance and reduces downtime. In terms of energy efficiency, while they may not surpass centrifugal pumps in energy consumption, their high volumetric efficiency makes them efficient in applications where fluid displacement is crucial.

Cost Considerations

Initial investment in swash plate pumps can be higher due to their larger size and complexity. However, their lower operational costs, especially in high-pressure scenarios, offset this investment. Long-term costs are influenced by factors like maintenance frequency and energy consumption. Gear pumps, with their potential for lower maintenance in some cases, can be a cost-effective alternative depending on the application.

Environmental Impact and Sustainability

Swash plate pumps, with their efficient energy use, contribute to lower carbon footprints, making them suitable for sustainable applications. However, their operation can still lead to energy waste in high-pressure settings. Companies should consider the balance between energy consumption and environmental regulations when choosing a pump type.

Case Studies and Real-World Applications

Success Stories

The Niger Delta Offshore Gas Project utilized Swash plate piston pumps for its challenging environment. Their reliability and efficiency in handling high pressures and abrasive fluids significantly improved production rates and reduced downtime.

Industry Examples

In water treatment facilities, gear pumps were replaced with Swash plate piston pumps, resulting in a 20% reduction in energy consumption and a 15% increase in pump lifespan. Similarly, oil and gas industries have seen enhanced efficiency in drilling operations through the use of these pumps.

Conclusion

Swash plate piston pumps offer a robust solution for various industrial applications, excelling in reliability and efficiency. While they may not be the first choice for high-pressure scenarios where centrifugal pumps prevail, their unique advantages in noise control and energy efficiency make them a viable option. By understanding the comparative advantages of centrifugal, gear, and Swash plate piston pumps, industries can make informed decisions tailored to their specific needs, ensuring optimal performance and sustainability.

ADD:No. 2 Tianchen Road, Yucheng High-tech Zone, Shandong

Copyright © www.highlandhydrostatic.com | Sitemap | Privacy Policy