Sizing Up Hydraulic Axial Piston Motors for Performance

Understanding the Basics: What is a Hydraulic Axial Piston Motor?

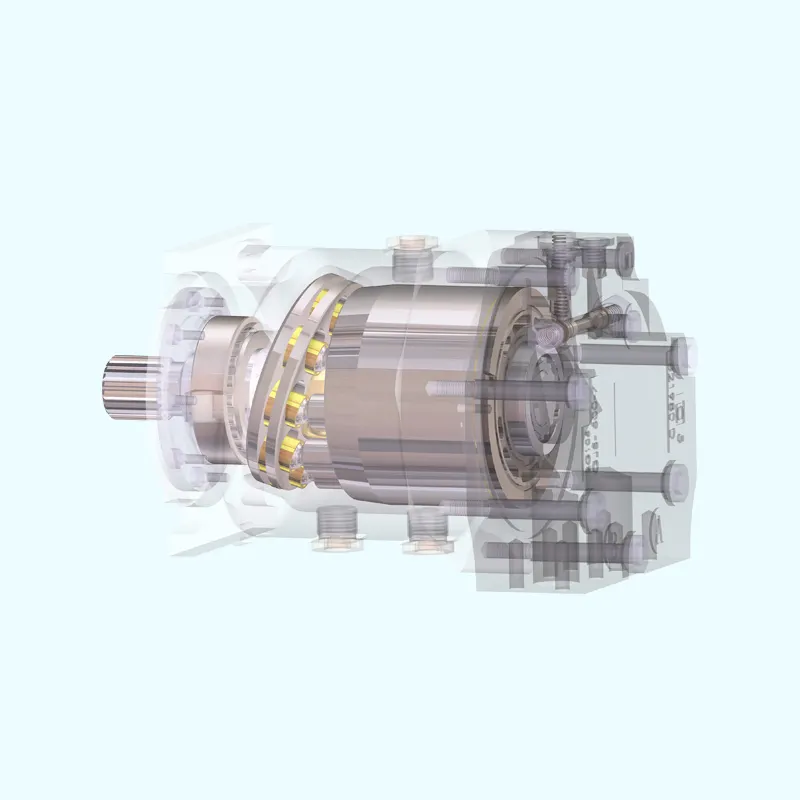

A hydraulic axial piston motor is a type of hydraulic actuator that converts hydraulic energy into mechanical rotational energy. It consists of a motor housing, cylinders, pistons, and a camshaft assembly. The camshaft rotates within the motor housing, causing the pistons in the cylinders to extend and retract, thereby generating rotational motion. This motion can then be transmitted to various machinery components, such as pumps, compressors, or machine tools.

The fundamental components of a hydraulic axial piston motor include:

- Piston Rings: These seals prevent leakage and ensure a tight seal between the piston and the cylinder walls.

- Rod Ends: The rods connect the piston to the camshaft, transferring force from the hydraulic fluid to the mechanical load.

- Camshaft Assembly: The camshaft converts the linear motion of the piston into rotational motion. Its design, including the number of lobes and their shape, significantly affects the motor's performance.

Understanding these components provides a foundational knowledge of how hydraulic axial piston motors operate. However, the true value lies in comprehending their performance metrics and how to select the appropriate motor for a given application.

Performance Metrics for Hydraulic Axial Piston Motors

When sizing a hydraulic axial piston motor, several performance metrics must be considered to ensure optimal performance. These metrics include:

- Displacement: This refers to the volume of fluid displaced by the piston during each stroke. It is measured in liters per revolution (L/rev) and is a critical factor in determining the motor's capacity.

- Pressure: The pressure of the hydraulic fluid within the system dictates the force generated by the motor. It is typically measured in megapascals (MPa) and must be sufficient to drive the machinery without causing excessive wear.

- Torque: Torque is the rotational force generated by the motor, measured in Newton-meters (Nm). It is directly related to the displacement and pressure, as higher pressure and displacement result in higher torque.

- Speed: The speed of the motor, measured in revolutions per minute (RPM), determines how quickly the motor can rotate the machinery. It is influenced by the pressure and displacement settings.

Each of these metrics plays a crucial role in the overall performance of the motor. For instance, a motor with high displacement and pressure will generate high torque, making it suitable for heavy-duty applications. Conversely, a motor with high speed is ideal for applications requiring rapid response, such as assembly lines.

Choosing the Right Sizing: Factors to Consider

Selecting the correct size and capacity of a hydraulic axial piston motor involves evaluating several factors:

- Load Requirements: The motor must be able to handle the maximum torque and rotational speed required by the machinery. If the motor is undersized, it may not meet the load requirements, leading to performance issues or equipment damage.

- Operating Conditions: Environmental factors such as temperature, pressure fluctuations, and contamination can affect the motor's performance and lifespan. Selecting a motor that is compatible with these conditions ensures longevity and reliability.

- Performance Goals: The desired output of the motor, such as maximum speed, efficiency, and reliability, must be aligned with the application's needs. For example, a motor used in a high-precision packaging machine may require higher accuracy and stability, whereas a motor used in a large-scale production line may prioritize speed and efficiency.

In addition to these general considerations, the material of construction is another important factor. Motors built from high-strength materials, such as steel or aluminum, can withstand greater stresses and offer better durability. However, the choice of material must be balanced against cost and weight, as heavier motors may not be suitable for high-speed applications.

Comparative Analysis: Axial vs. Radial Piston Motors

In the world of hydraulic motors, axial piston motors are not the only option available. Radial piston motors, also known as circular piston motors, offer distinct advantages and are suited to different types of applications. While both types convert hydraulic energy into mechanical motion, they do so in different ways.

The primary difference between axial and radial piston motors lies in the orientation of the pistons relative to the camshaft. In axial motors, the pistons are aligned with the axis of rotation, resulting in a high volumetric displacement but lower mechanical efficiency. Radial motors, on the other hand, have pistons perpendicular to the axis, which increases mechanical efficiency but decreases volumetric displacement.

This difference impacts the performance characteristics of the motors. Axial motors are typically better suited for low-pressure, high-flow applications, such as pumps and fluid control systems, where efficiency is less critical than the ability to handle large volumes of fluid. Radial motors, with their higher efficiency, are ideal for high-pressure applications, such as machine tools and industrial machinery where torque and speed are paramount.

Understanding these differences is crucial when selecting the right motor for a specific application. For example, a hydraulic motor used in a machine tool that requires precise control and high efficiency would benefit from a radial design. Conversely, a motor used in a large-scale construction project, where volume flow and reliability are key, might be better served by an axial design.

Calculating Hydraulic Axial Piston Motor Sizing: Practical Examples

Calculating the appropriate size and capacity of a hydraulic axial piston motor involves a series of steps and considerations. Below is a step-by-step guide to determining the required motor size:

- Determine the Required Flow Rate: The flow rate (Q) is the volume of hydraulic fluid that must pass through the motor per unit of time. It is calculated using the formula:

[

Q = \frac{V \times n}{60}

]

Where:

- ( V ) is the displacement (in liters per revolution)

- ( n ) is the speed (in revolutions per minute)

Calculate the Pressure Loss: Pressure loss occurs due to the resistance in the hydraulic system, including the motor itself, fittings, and other components. The allowable pressure (P_allowable) is typically determined based on the system's requirements and the motor's specifications.

Determine the Torque Requirements: Torque (T) is the rotational force generated by the motor and is calculated using the formula:

[

T = Q \times P

]

Where:

- ( Q ) is the flow rate (in liters per minute)

- ( P ) is the pressure (in megapascals)

- Select the Motor Size: Using the calculated torque and flow rate, consult the motor's specifications to determine the appropriate size and displacement. Ensure that the selected motor can handle the calculated torque and flow rate under the operating conditions.

For example, suppose a hydraulic system requires a flow rate of 2 liters per minute at a pressure of 10 MPa. Using the formula above, the torque would be:

[

T = 2 \times 10 = 20 \, \text{Nm}

]

Consulting the motor's specifications, a motor with a displacement of 0.5 liters per revolution and a speed of 200 RPM would provide the necessary torque and flow rate. The calculation would be:

[

Q = \frac{0.5 \times 200}{60} \approx 1.67 \, \text{L/min}

]

However, this falls short of the required flow rate, so a motor with a larger displacement or higher speed would be necessary.

Case Study: Successful Application of Hydraulic Axial Piston Motors

To illustrate the practical application of hydraulic axial piston motors, consider a manufacturing plant that specializes in the production of heavy machinery. The plant's operations require the use of large-scale machinery that demands high torque and precision. The plant's engineers selected hydraulic axial piston motors to power their heavy-duty machinery, replacing older, less efficient rotational motors.

Before the switch, the plant experienced frequent downtime and high maintenance costs due to the older motors' inefficiency and reduced performance. After implementing the hydraulic axial piston motors, the plant noticed several improvements:

Increased Productivity: The new motors provided the machinery with the power and torque needed to operate at full capacity, reducing downtime and increasing production rates.

Reduced Maintenance Costs: The improved efficiency of the hydraulic axial piston motors minimized wear and tear, leading to lower maintenance and replacement costs.

Extended Motor Lifespan: The motors' high durability and compatibility with the plant's hydraulic system extended their operational lifespan, reducing the need for frequent replacements.

A detailed analysis of the motor's performance revealed that the axial design was ideal for the application's requirements. The high displacement and torque capabilities ensured that the motors could handle the machinery's demanding workloads, while the design's resistance to wear and tear contributed to their longevity.

Balancing Performance and Efficiency

In conclusion, hydraulic axial piston motors are versatile and powerful components that play a crucial role in a wide range of industrial applications. Selecting the right motor for a specific application requires careful consideration of performance metrics, load requirements, and operating conditions. By understanding the fundamental principles of hydraulic axial piston motors, their performance characteristics, and how to size them appropriately, you can ensure optimal performance and efficiency in your hydraulic systems.

ADD:No. 2 Tianchen Road, Yucheng High-tech Zone, Shandong

Copyright © www.highlandhydrostatic.com | Sitemap | Privacy Policy