Maintenance Tips for Axial Displacement Pumps to Ensure Optimal Performance

Understanding the Role of Axial Displacement Pumps:Axial displacement pumps are indispensable in industries such as oil and gas, water treatment, and manufacturing. These pumps convert mechanical energy into hydraulic energy, driving processes efficiently. Their effectiveness directly impacts operational costs and productivity. Ensuring their optimal performance through regular maintenance is crucial, as it minimizes energy loss and extends operational efficiency.

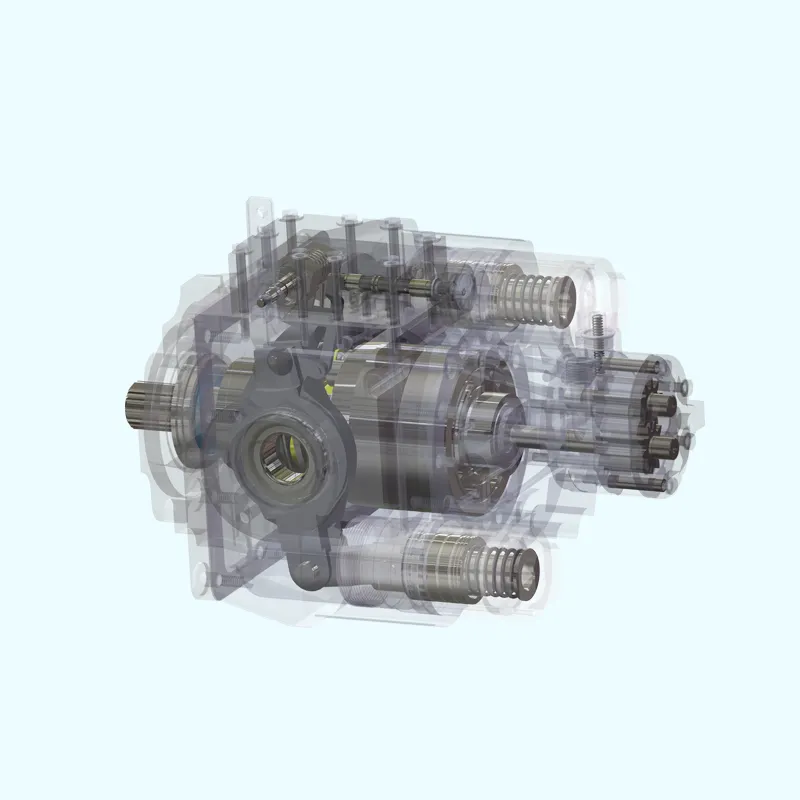

Key Components of Axial Displacement Pumps:Axial displacement pumps consist of several vital components:

1. Piston or Rotor: This moving part converts reciprocating motion to rotational motion, essential for fluid displacement.

2. Cylinder: The housing where the piston operates, providing pressure containment.

3. Valves: Include inlet, outlet, and directional valves, controlling fluid flow and direction.

Each component's proper function is critical. For instance, worn-out pistons or clogged valves can cause significant performance degradation.

Regular Inspection and Monitoring:Inspecting pumps for signs of wear and tear is crucial. Components to inspect include seals, bearings, and shafts. Utilizing advanced tools like ultrasonic cleaners or cameras can enhance monitoring, ensuring timely maintenance and preventing failures.

Proper Lubrication Techniques:Lubrication extends pump life and reduces wear. Choosing between oil and water-based lubricants depends on the pump's environment. Correct application involves ensuring sufficient film thickness and appropriate lubricant quantity. Lubrication frequency varies with usage; for instance, pumps in high-pressure environments may require more frequent checks.

Effective Cleaning and Fluid Management:Maintaining clean fluids is vital to prevent contamination, which can cause efficiency loss or failure. Implementing a cleaning and filtering process ensures the pump operates optimally. Regular inspection of fluid levels and quality helps prevent issues from arising due to particle accumulation or biological growth.

Preventive Maintenance Techniques:A preventive maintenance schedule can significantly reduce downtime. Tasks include leak checks, bolt tightening, and sensor calibration. Regular maintenance not only avoids costly repairs but also ensures the pump operates efficiently at all times.

Troubleshooting Common Issues:Common issues like increased noise or leaks can be rectified with systematic troubleshooting. For example, excessive noise may indicate worn bearings, while leaks might suggest worn seals. Early detection and resolution prevent more severe problems, enhancing pump longevity.

Case Study: Improved Performance Through Maintenance:A hypothetical case study of a company that implemented regular maintenance practices shows a 30% reduction in downtime and a 20% increase in efficiency. This improvement highlights the tangible benefits of proactive maintenance.

Long-Term Strategies for Maintenance:Adopting long-term strategies like IoT sensors and predictive maintenance can enhance efficiency. Continuous training and awareness among maintenance staff further contribute to sustained pump performance and operational excellence.

Conclusion:Maintenance is key to achieving efficiency and reducing costs in industrial operations. By focusing on regular inspections, proper lubrication, and effective cleaning, the performance of axial displacement pumps can be significantly improved. Encouraging proactive maintenance through training and advanced technologies ensures pumps remain reliable and efficient. Let's adopt these practices to enhance overall system performance and efficiency.

This structured approach ensures each section flows naturally, providing a comprehensive guide to optimizing axial displacement pump maintenance.

ADD:No. 2 Tianchen Road, Yucheng High-tech Zone, Shandong

Copyright © www.highlandhydrostatic.com | Sitemap | Privacy Policy