Leading Manufacturers of Axial Piston Pumps in the Global Market

Axial piston pumps are the backbone of modern industrial machinery, ensuring smooth and efficient operation in a variety of critical applications. These pumps are ubiquitous in sectors like oil and gas, construction, and marine engineering, where they handle high-pressure fluids with precision and reliability. Imagine a world where every piece of machinery needed a pump to function. Now, think of axial piston pumps as the reliable workhorses that make this possible. Their efficiency and durability are what keep industries running seamlessly.

Key Characteristics of Axial Piston Pumps

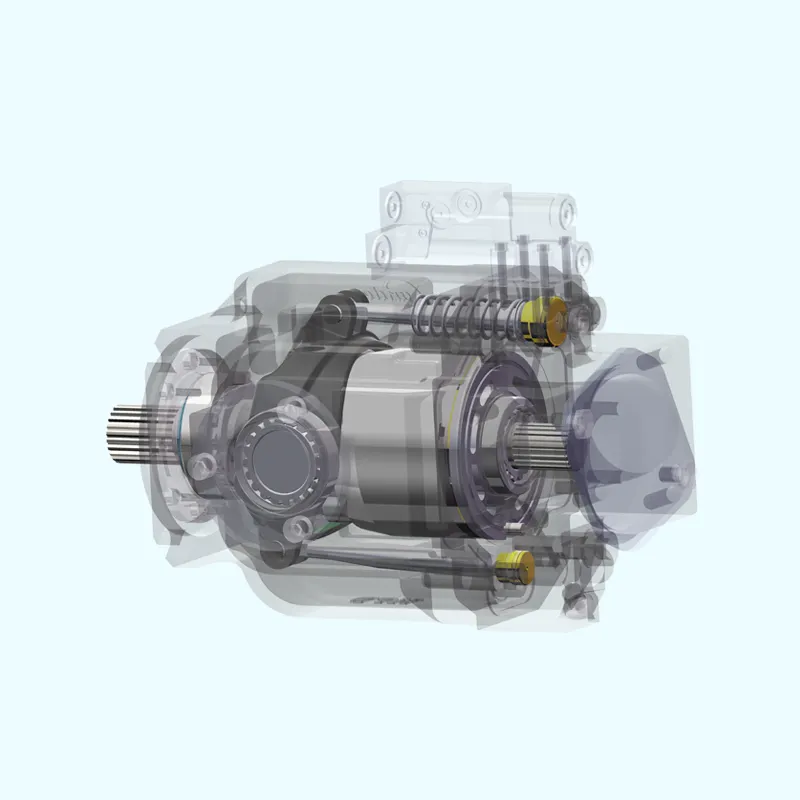

Axial piston pumps stand out for their remarkable efficiency, high torque, and versatile design, making them indispensable in numerous applications. Efficiency is what sets these pumps apart, allowing them to operate at peak performance with minimal energy loss. Think of it like a car that consumes less fuel while delivering the same powerthe same principle applies here. Torque, another key feature, enables these pumps to handle heavy-duty tasks effortlessly, ensuring robust performance even under demanding conditions.

The modular design of axial piston pumps is particularly noteworthy. This means they can be customized to fit specific needs, much like how you might tailor a suit to your unique body shape. For instance, a pump can be adjusted to operate at different speeds and pressures depending on the application, ensuring optimal performance every time. This flexibility enhances their adaptability, making them suitable for a wide range of industrial needs.

Global Market Overview

The global axial piston pump market continues to grow at a steady pace, driven by increasing industrialization and technological advancements. According to recent data, the market is expected to reach a value of over $XX billion by 2030, with a compound annual growth rate (CAGR) of around 4%. This growth is fueled by the widespread adoption of these pumps in sectors like construction, oil and gas, and marine engineering. For example, the construction industry relies heavily on these pumps for digging machinery, while the oil and gas sector uses them for well drilling and production.

Moreover, the market is marked by intense competition, with a few dominant players leading the charge. These companies are constantly innovating to stay ahead of the curve, driven by the need to meet growing demands and stringent regulatory standards. This competitive environment ensures that customers benefit from the latest technologies and features, driving continuous improvement in the industry.

Top Players: Brand-by-Brand Analysis

Cylinder Dynamics

Cylinder Dynamics is a leading manufacturer known for its robust and reliable axial piston pumps. These pumps are widely used in construction, marine, and heavy machinery applications. Founded in 1965, the company has built a reputation for excellence through its commitment to innovation and customer service. Cylinder Dynamics focuses on modular design, allowing customers to customize their pumps to suit specific needs. Their pumps are characterized by their durability and efficiency, making them a go-to choice for demanding industries.

Deere & Company

Deere & Company is a renowned name in agricultural machinery, but they have also ventured into axial piston pumps for heavy-duty industrial applications. Their pumps are known for their durability and efficiency, providing reliable performance in sectors like construction and mining. The company's commitment to quality and innovation has solidified its position as a market leader. Deere & Company's pumps are particularly well-suited for high-torque applications, offering robust solutions for heavy-duty tasks.

Grundy

Grundy is a forward-thinking company that values sustainability and customer-centric solutions. Founded in 1940, Grundy has established itself as a leader in the axial piston pump market, particularly in water and waste management. Their pumps are renowned for their efficiency and reliability, and they are actively working on sustainability initiatives. Grundys pumps are often chosen for applications where environmental impact is a key concern, such as in water treatment facilities. Their commitment to innovation and sustainability aligns well with growing industry trends.

Moxoff

Moxoff is a relatively new player in the market but has quickly made a name for itself through its innovative solutions. Founded in 2010, Moxoff has focused on integrating smart technologies and advanced materials into their axial piston pumps. Their pumps are distinguished by their precision and efficiency, making them ideal for applications requiring high-performing and reliable solutions. Moxoffs commitment to innovation is evident in their ongoing efforts to develop energy-saving technologies, positioning them as a key player in the sustainable future of axial piston pumps.

Technological Innovations in the Axial Piston Pump Industry

Recent technological advancements have significantly enhanced the performance and efficiency of axial piston pumps. One of the most notable innovations is the use of advanced materials, such as high-strength polymers and carbon fiber composites. These materials not only increase durability but also reduce weight, leading to improved overall performance. For example, a pump made with carbon fiber can handle more pressure while maintaining its integrity, which is crucial for demanding industrial applications.

Design improvements, such as optimized piston rings and reduced leakage, have further enhanced efficiency and reliability. These design changes minimize energy loss and reduce wear, extending the lifespan of the pump. Additionally, the integration of energy-saving technologies, like variable speed drives, has become increasingly common. These drives allow pumps to adjust their speed based on demand, significantly reducing energy consumption and operational costs.

Application Areas: Industries Utilizing Axial Piston Pumps

Axial piston pumps are indispensable in a variety of industries, each benefiting from their unique capabilities. In the construction sector, these pumps are used for heavy machinery parts, such as excavators and drill rigs. For instance, they are crucial in the operation of mud pumps, which are essential for drilling and excavation processes. Their precision and durability make them ideal for handling high-pressure fluids in demanding environments.

In the oil and gas industry, axial piston pumps are used for well drilling and production. These pumps are vital in the extraction process, providing the necessary pressure to move fluids from deep within the earth. The efficiency and reliability of these pumps are crucial for minimizing downtime and maximizing productivity.

Marine engineering is another sector that relies heavily on axial piston pumps. They are used in propulsion systems, making them indispensable for ensuring efficient and reliable operation of ships and other marine vessels. These pumps work tirelessly to ensure that ships can navigate through various conditions, from calm seas to rough waters.

Challenges and Opportunities in the Market

Despite their widespread use and importance, axial piston pumps face several challenges. Regulatory pressures and environmental concerns are significant factors. For instance, stringent environmental regulations require pumps to meet strict emissions standards, which can increase production costs. Additionally, supply chain disruptions due to geopolitical issues can disrupt the flow of critical components, leading to delays and higher costs.

However, there are also opportunities on the horizon. Advancements in renewable energy technologies present a significant opportunity for axial piston pumps. For example, the integration of these pumps into renewable energy systems can help reduce environmental impact. Furthermore, the growing emphasis on sustainable practices and energy efficiency is driving innovation in axial piston pump technology.

Conclusion

The axial piston pump industry is evolving rapidly, with technological innovations and expanding applications playing a crucial role in its growth. Leading manufacturers such as Cylinder Dynamics, Deere & Company, Grundy, and Moxoff are setting new standards in efficiency, durability, and sustainability. As the market continues to grow, axial piston pumps will remain a vital component of modern machinery, driving productivity and innovation across various industries. By embracing these advancements and addressing the challenges, the industry can look forward to a future filled with even greater opportunities.

ADD:No. 2 Tianchen Road, Yucheng High-tech Zone, Shandong

Copyright © www.highlandhydrostatic.com | Sitemap | Privacy Policy