Hydraulic Test Bench for Sale: Features, Benefits, and More

Features of Hydraulic Test Benches

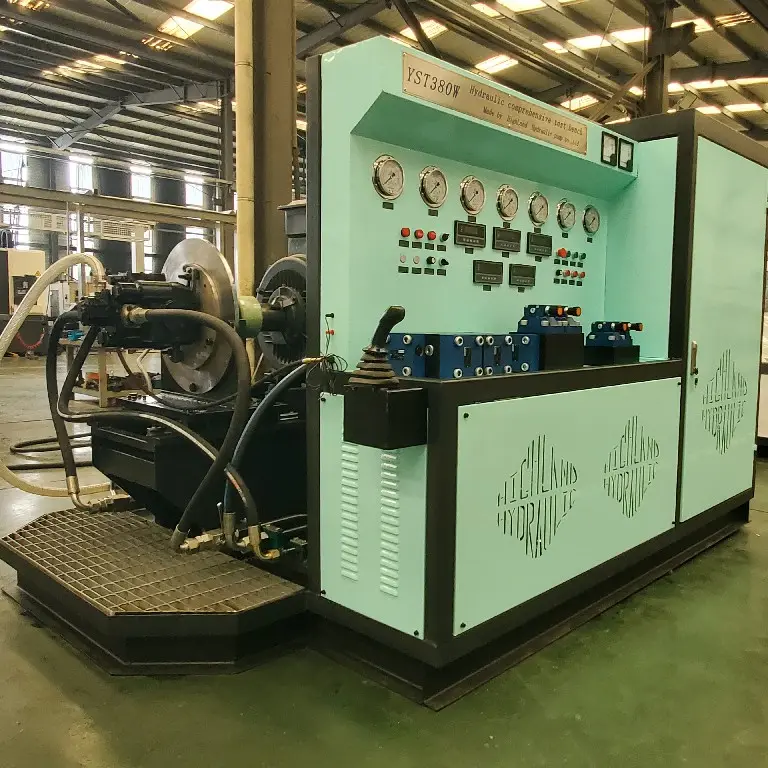

Hydraulic test benches come equipped with a variety of features designed to meet the diverse needs of different testing scenarios. Some of the key features include:

1. Wide Pressure Range: Modern test benches can handle a broad spectrum of pressure settings, from low-pressure testing to high-pressure systems. This feature is crucial for testing hydraulic components that operate under varying conditions. For example, in aerospace applications, the bench must simulate the pressure fluctuations experienced during flight. This versatility ensures that all types of hydraulic systems can be thoroughly tested.

2. Adjustable Flow Capability: The flow rate can be finely tuned to simulate real-world fluid dynamics. This capability is essential for evaluating the performance of hydraulic systems under different flow scenarios. For instance, in automotive applications, this feature helps in verifying the efficiency of braking systems under various load conditions. By accurately simulating real-world conditions, the bench ensures realistic performance data.

3. Diverse Test Fixtures: These benches are equipped with a range of test fixtures, such as pumps, valves, and accumulators. This diversity allows for comprehensive testing of various hydraulic components to ensure they work seamlessly together. For example, manufacturers can use these benches to test the compatibility of different hydraulic components in manufacturing machinery, ensuring that all parts function in harmony.

4. Sealed Mechanisms: To prevent contamination and ensure the longevity of the bench, many hydraulic test benches feature sealed components. This design not only protects the system but also maintains optimal operating conditions. For example, in energy applications, sealing mechanisms help in maintaining the cleanliness and integrity of hydraulic fluids used in renewable energy systems, thereby extending the lifespan of the components.

5. User-Friendly Design: Modern test benches are designed with intuitive controls and user-friendly interfaces. This feature is particularly important for technicians who may not be as experienced, ensuring that the bench remains accessible and easy to operate. For instance, in an engineering workshop, this feature makes it easier for maintenance staff to perform routine tests and maintenance tasks, reducing the learning curve for new technicians.

Benefits of Using Hydraulic Test Benches

The benefits of using hydraulic test benches are numerous and can significantly impact your operations. Some of the key benefits include:

1. Improved Reliability: Regular testing helps identify potential issues early, which can lead to better reliability of hydraulic systems and reduced downtime. For example, in aerospace, regular testing can prevent catastrophic failures during critical operations, ensuring the safety and reliability of aircraft hydraulic systems.

2. Enhanced Safety: Hydraulic test benches provide a controlled environment for testing, minimizing the risk of accidents during maintenance activities. This controlled environment ensures that all potential hazards are managed effectively. In the automotive industry, controlled testing environments help prevent accidents during maintenance and repair, enhancing the safety of vehicles.

3. Cost Savings: Proper testing can prevent costly repairs and extend the lifespan of hydraulic systems, leading to significant cost savings in the long run. For instance, in manufacturing, regular testing can identify and address issues before they become major problems, reducing the need for emergency repairs, which often involve high labor and material costs.

4. Efficiency in Maintenance: By allowing for thorough testing, hydraulic test benches enable proactive maintenance, ensuring that systems operate at peak efficiency. For example, in the energy sector, proactive maintenance can optimize the performance of hydraulic systems in renewable energy installations, maximizing efficiency and output.

Applications of Hydraulic Test Benches

Hydraulic test benches are versatile tools used across various industries. Some of the key applications include:

1. Aerospace: Testing hydraulic systems in aircraft to ensure they operate reliably under different conditions. For instance, test benches help validate the performance of hydraulic systems during critical phases of flight, such as takeoff and landing. This testing is essential to ensure that the hydraulic systems meet stringent safety standards.

2. Automotive: Evaluating braking systems, transmission, and other hydraulic components for automotive applications. Test benches are essential for ensuring the safety and reliability of these systems during the design and manufacturing process. For example, in the development of new vehicle models, test benches can verify the performance of braking systems under various testing conditions, ensuring they meet safety standards.

3. Manufacturing: Conducting quality control tests on hydraulic machinery and prototypes. These benches help manufacturers ensure that their products meet the required standards before being released to the market. For instance, in a manufacturing facility, hydraulic test benches can be used to test the performance of hydraulic pumps and other components, ensuring that they function correctly in various manufacturing processes.

4. Energy: Assessing hydraulic components in renewable energy systems for efficiency and safety. For example, test benches help in validating the performance of hydraulic systems used in wind turbines and solar energy installations. This testing ensures that the hydraulic systems operate efficiently and safely, contributing to the overall performance of renewable energy installations.

How to Select the Right Hydraulic Test Bench

Choosing the right hydraulic test bench involves considering specific testing requirements, budget, and manufacturer reliability. Key factors to consider include:

1. Testing Requirements: Define what needs to be tested, such as pressure, flow, or component performance. For example, in aerospace, testing requirements may include simulating altitude changes and other environmental factors. Clearly defining your testing needs will help in selecting a test bench that can meet these requirements.

2. Budget: Determine the financial constraints to select a bench that offers value for money. For example, a budget may be set to ensure that the test bench meets the operational needs without overextending the budget. This step is crucial to ensure that you invest in a bench that fits within your budget while still providing the necessary capabilities.

3. Manufacturer Reputation: Research manufacturers for quality, support, and after-sales service. For instance, choosing a reputable manufacturer ensures that you receive reliable support and service, crucial for maintaining the bench over its lifespan. Consider factors such as warranty, service agreements, and customer reviews to make an informed decision.

Conclusion

Hydraulic test benches are vital tools for ensuring the reliability and efficiency of hydraulic systems across various industries. By understanding their features, benefits, and applications, you can make an informed decision on purchasing one. Whether for aerospace, automotive, or manufacturing, a hydraulic test bench enhances system testing and maintenance, ultimately contributing to safer and more efficient operations.

Consider the factors discussed here and choose a test bench that meets your specific needs for a reliable testing solution. With the right test bench, you can ensure that your hydraulic systems operate at their best, providing peace of mind and enhanced performance.

ADD:No. 2 Tianchen Road, Yucheng High-tech Zone, Shandong

Copyright © www.highlandhydrostatic.com | Sitemap | Privacy Policy