Exploring the Advantages and Disadvantages of Axial Piston Variable Pumps

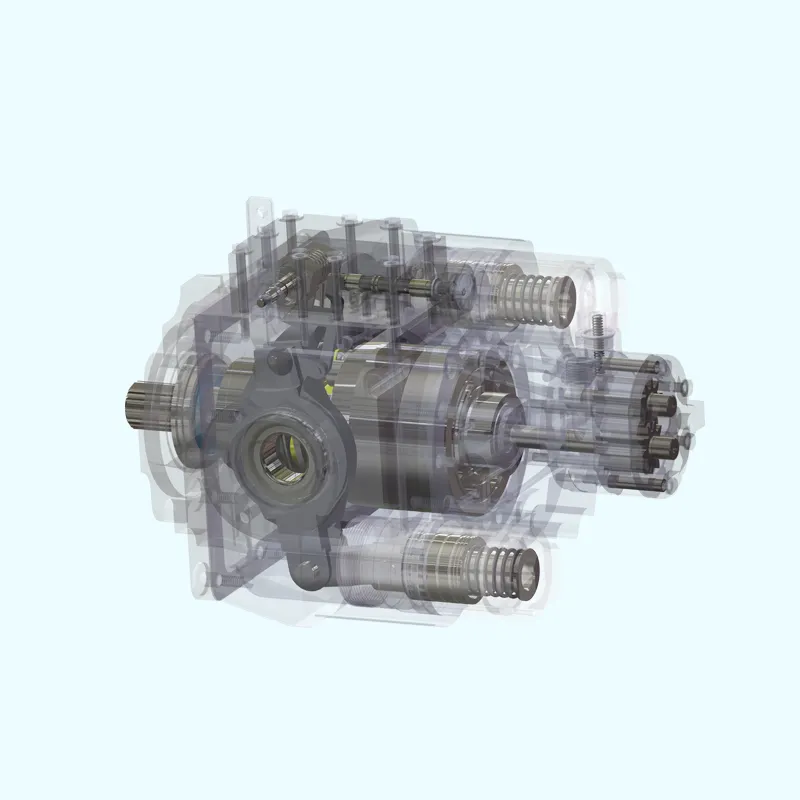

Axial piston variable pumps operate by converting rotational motion into linear motion, which is controlled through precise components. The primary components include the swashplate, pistons, hydraulic fluid, and the pump housing.

1. Swashplate: At the heart of the pump is the swashplate, which rotates and moves axially. By adjusting the angle of the swashplate, the pump can control the displacement, effectively managing the volume of fluid that it delivers. This angle adjustment allows the pump to operate at different speeds and flows, making it highly versatile.

2. Pistons: The pistons within the pump are designed to extend and retract as the swashplate rotates. This linear motion is what drives the hydraulic fluid, converting the rotational energy into hydraulic power.

3. Hydraulic Fluid: The fluid serves as the working medium, transferring energy and ensuring smooth operation. The choice of fluid is critical and can impact the pump's performance and longevity.

4. Pump Housing: The pump housing contains the other components, providing structural support and ensuring a watertight seal to prevent leaks.

The mechanism of an axial piston variable pump is both elegant and intricate. As the swashplate rotates, it causes the pistons to extend and retract, and the hydraulic fluid is displaced, producing the necessary fluid flow. This variable displacement allows the pump to adjust the output based on the specific needs of the system.

Advantages of Axial Piston Variable Pumps

Axial piston variable pumps offer several advantages that make them highly desirable in various applications.

1. High Efficiency: These pumps are designed to be highly efficient, with minimal energy loss due to friction and wear. This makes them suitable for applications where energy efficiency is a primary concern.

2. Wide Range of Displacement: One of the most significant advantages is their ability to adjust the displacement over a wide range. This flexibility allows the pump to match its output to the specific requirements of the application, ensuring optimal performance and reduced energy consumption.

3. Excellent Load and Speed Control: Axial piston variable pumps provide precise control over both load and speed, making them ideal for applications that require dynamic flow control. This is particularly important in industries like hydraulics and automation.

4. Reliability and Durability: Built with precision and high-quality materials, these pumps offer long service life and reliable performance. They are resistant to wear and tear, making them a durable choice for industrial applications.

Disadvantages of Axial Piston Variable Pumps

Despite their many benefits, these pumps come with some drawbacks that need to be addressed.

1. Higher Cost: Compared to fixed-displacement pumps, axial piston variable pumps are more expensive. This higher cost is due to their complex design and the need for specialized components.

2. Complexity in Maintenance: The precision components of axial piston variable pumps require specialized tools and expertise for maintenance. This can make them more time-consuming and costly to service compared to fixed-displacement pumps.

3. Higher Energy Consumption: While these pumps are highly efficient, they still consume more energy compared to fixed-displacement pumps, especially when operating over a range of speeds and displacements.

4. Potential for Wear and Tear: Over time, axial piston variable pumps can experience wear and tear on components like the swashplate, pistons, and hydraulic fluid. This can lead to reduced performance and the need for costly repairs or replacements.

Understanding these advantages and disadvantages is crucial when selecting the right pump for your application.

Comparative Analysis with Other Types of Pumps

Axial piston variable pumps are often compared with radial piston pumps and fixed-displacement pumps. Each type of pump has its own strengths and weaknesses, and the choice between them depends on the specific requirements of the application.

1. Radial Piston Pumps: Radial piston pumps deliver a constant flow rate and are simpler in design, making them easier to maintain. However, they are less efficient and not suitable for applications that require precise flow control.

2. Fixed-Displacement Pumps: Fixed-displacement pumps deliver a constant flow rate and are suitable for applications where stability is more important than flexibility.

The choice between axial piston variable pumps and other types depends on factors such as the required flow rate, the need for variable displacement, and the importance of energy efficiency.

Real-World Applications and Case Studies

Axial piston variable pumps are widely used in various industries, including automotive, aerospace, and marine. Here are some real-world applications:

1. Earthmoving Equipment: In construction machinery, axial piston variable pumps are used to power hydraulic excavators, bulldozers, and dump trucks. Their ability to adjust the flow rate allows operators to manage the power output according to the specific needs of the task.

2. Marine Propulsion: In ships and offshore equipment, axial piston variable pumps are used to drive machinery such as pumps, compressors, and generators. Their high efficiency and variable displacement make them ideal for controlling the flow of hydraulic fluids in demanding environments.

3. Industrial Machinery: In factories and manufacturing plants, axial piston variable pumps are used to power hydraulic machines such as presses, grinders, and hoists. Their flexibility allows operators to adjust the flow rate to match the speed and load of the machinery.

These applications demonstrate the versatility and effectiveness of axial piston variable pumps in meeting the diverse needs of modern industrial systems.

Future Trends and Innovations in Axial Piston Variable Pumps

The future of axial piston variable pumps looks promising. Innovations in design, materials, and control systems could lead to further improvements in performance and reliability.

1. Design Improvements: Advances in materials science and manufacturing could lead to more durable and efficient pumps. For example, the use of advanced tribological materials could reduce friction and wear, improving the pump's performance over time.

2. Integration with IoT Technologies: The integration of sensors and IoT technologies could enhance the pumps performance by allowing real-time monitoring and control. This could enable predictive maintenance and optimize energy usage.

3. Energy Efficiency: Innovations in pump design could lead to further improvements in energy efficiency, making axial piston variable pumps even more competitive in the energy-sensitive industries.

These trends highlight the potential for axial piston variable pumps to remain a key component of hydraulic systems in the future.

Balancing Pros and Cons

Axial piston variable pumps offer a range of advantages, including high efficiency, variable displacement, excellent load and speed control, and reliability. However, they also come with some disadvantages, such as higher cost, complexity in maintenance, and potential for wear and tear.

When selecting a pump for a specific application, it is essential to consider the unique requirements of the system and weigh the pros and cons accordingly. While axial piston variable pumps may not be the best choice for all applications, their versatility and performance make them a valuable tool in the hydraulic systems toolkit. By carefully evaluating the needs of the system, operators can make informed decisions that optimize performance and achieve their goals.

By understanding the advantages and disadvantages, the core components, and the real-world applications, you can choose the right pump for your specific needs.

ADD:No. 2 Tianchen Road, Yucheng High-tech Zone, Shandong

Copyright © www.highlandhydrostatic.com | Sitemap | Privacy Policy