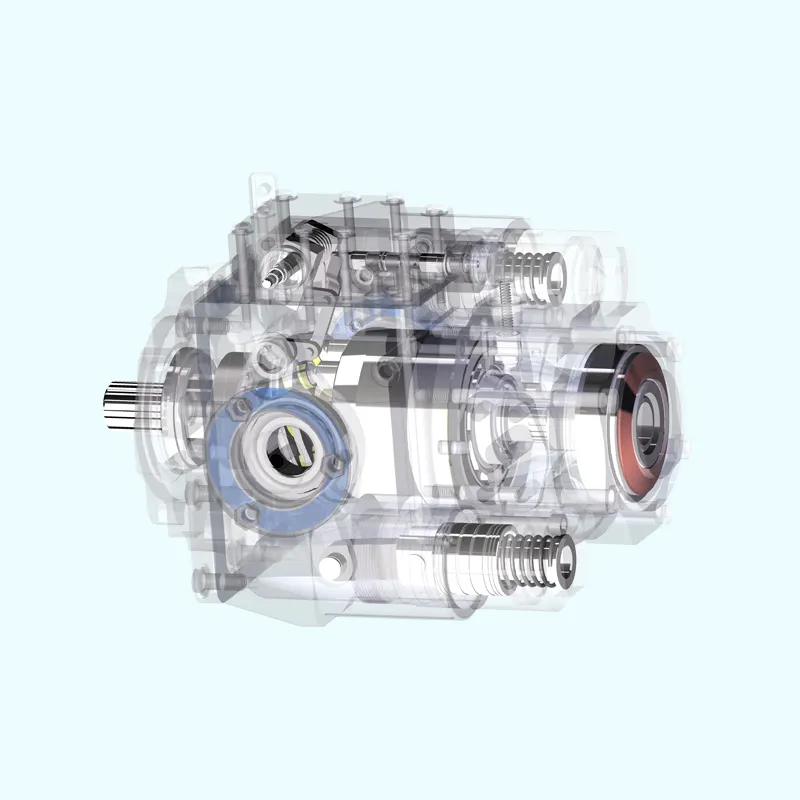

Discover the Current Axial Piston Pump Price Trends

Factors Influencing Axial Piston Pump Prices

The pricing of axial piston pumps is influenced by several key factors. Material costs, notably metals like steel and tributaries, significantly impact the final price. For instance, fluctuations in steel prices can either increase or decrease pump costs. Additionally, production costs, including labor and energy consumption, play a crucial role. Higher labor costs in regions like North America tend to drive up pump prices, while more affordable labor in Asia keeps costs lower.

Geopolitical events, such as trade disputes, can also affect pump prices. In recent years, tensions between major trading nations have disrupted supply chains, leading to price volatility. Increasing demand in regions with robust manufacturing sectors can lead to higher prices due to limited supply. Conversely, lower demand in downturned regions can drive prices down.

Regional Price Comparisons

Comparing axial piston pump prices across regions reveals distinct trends. In North America, the advanced manufacturing base generally results in higher pump prices due to elevated labor costs and stringent regulatory requirements. Europe, on the other hand, exhibits cost variations based on the availability of rare earth minerals, which are critical for manufacturing these pumps. Asia, particularly countries like China, often features lower prices, benefiting from economies of scale and intense competition.

Technological Advancements and Their Impact

Recent technological advancements in axial piston pumps have reshaped the market. Enhanced efficiency, automation, and energy-saving features can justify higher prices by improving pump performance. For example, pumps with advanced control systems can reduce operational costs and enhance overall efficiency. Companies investing in R&D are strategically positioning themselves for future price trends, balancing the costs of innovation against market demands.

Future Price Forecasting

Forecasting axial piston pump prices involves considering economic factors such as inflation and recessions. These macroeconomic conditions can significantly influence demand and supply. Geopolitical events, such as trade wars or supply chain disruptions, can cause sudden price fluctuations. Environmental regulations, particularly those concerning emissions, may lead to technological upgrades and higher prices. Market analysts predict that companies will strategically adjust pricing based on these factors, while investing in new technologies could offer long-term competitive advantages.

Case Study: Impact of Supply Chain Disruptions

The COVID-19 pandemic caused significant supply chain disruptions, affecting axial piston pump prices globally. Regions reliant on imported materials faced increased costs, while countries with diversified supply chains managed price volatility more effectively. For example, disruptions led to a shortage of key components, pushing up prices. This case study highlights how geopolitical events can disrupt market dynamics, forcing companies to adapt by either raising prices or enhancing internal efficiency to maintain market competitiveness.

Navigating the Evolving Landscape

In conclusion, axial piston pump prices are profoundly influenced by material costs, production dynamics, regional economic conditions, technological advancements, and global events. Understanding these factors is essential for businesses to navigate the market effectively. By staying informed about technological developments and economic trends, stakeholders can make informed decisions to enhance their competitiveness.

To stay ahead, its crucial to monitor market trends and be flexible in adjusting strategies. The future of axial piston pumps will be shaped by continuous innovation and adaptation to market needs. Stay informed and positioned to capitalize on the ever-changing market landscape.

ADD:No. 2 Tianchen Road, Yucheng High-tech Zone, Shandong

Copyright © www.highlandhydrostatic.com | Sitemap | Privacy Policy