Design Innovations Driving the Evolution of Variable Displacement Motors

In the ever-evolving landscape of machinery, variable displacement motors stand out as a revolutionary advancement, fundamentally reshaping industries from automotive to manufacturing. These motors are not just about changing speed; they are about efficiency, versatility, and performance enhancement. As we delve into the future, it's clear that these motors are here to stay, thanks to cutting-edge innovations and smart control systems.

Understanding the Basics of Variable Displacement

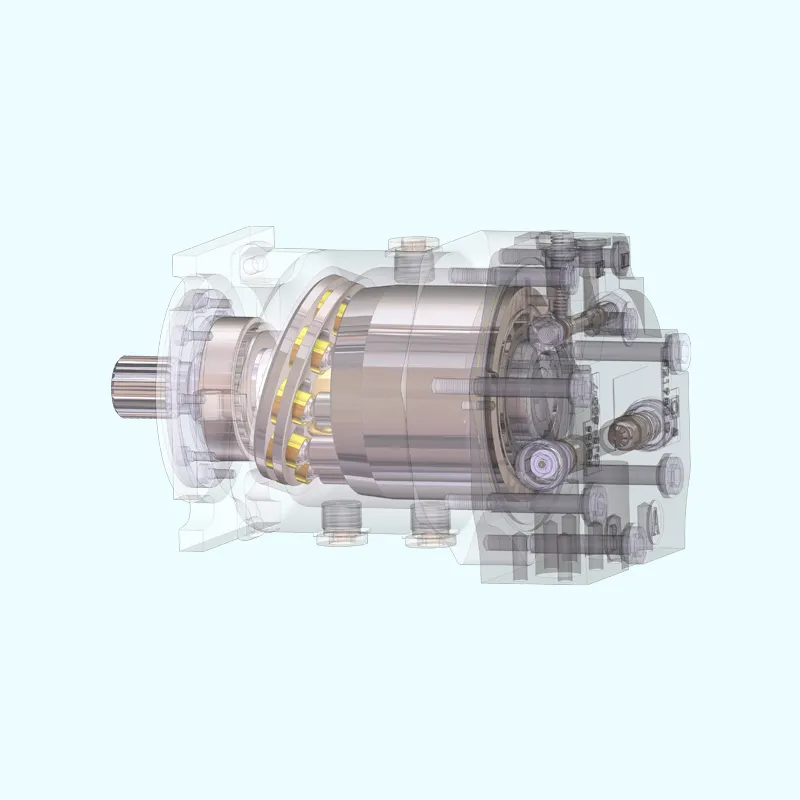

At the heart of variable displacement motors lies a simple yet profound concept: adjusting the volume of fluid within the motor to achieve optimal speed and torque. Unlike traditional fixed-displacement motors, these motors can adapt their displacement based on operational needs. Imagine a piston moving within a cylindernot just up and down, but adjusting its position to alter the motors performance. This dynamic adjustment ensures the motor operates at peak efficiency, regardless of the specific task it's performing.

Variable displacement operates at a molecular level, where tiny changes in fluid volume translate into significant performance gains. The principle is straightforward: by changing the effective area of the piston's movement, the motor can achieve different speeds and torques. This adaptability is key to its versatility across various industries. In industrial manufacturing, these motors can switch seamlessly between high and low speeds to handle different tasks efficiently. In automotive applications, they enable more efficient fuel usage and reduced emissions.

Key Innovations in Variable Displacement Technology

Recent advancements have pushed the boundaries of what's possible with variable displacement motors. Innovations in internal components, such as advanced pistons, smarter valves, and improved pumps, have significantly enhanced performance. For instance, new materials have increased the durability of these components, while innovative designs have improved energy efficiency. These tweaks ensure that motors not only perform better but also last longer, reducing maintenance needs and operational costs.

One notable innovation is the use of smart materials in pistons, which can change shape and volume based on temperature and pressure. This flexibility allows the motor to maintain optimal performance under varying conditions. Additionally, advanced valves and pumps can dynamically adjust their flow rates, further optimizing the motors efficiency. These next-generation components ensure that variable displacement motors are more reliable and efficient than ever before.

Advanced Control Systems: Smarter Motors

The integration of advanced control systems represents another significant leap forward. Electronic governors and smart sensors enable real-time adjustments, optimizing the motors performance dynamically. Think of these systems as the motors' own helpers, constantly monitoring and responding to changes, ensuring maximum efficiency and minimal energy waste.

For example, electronic governors can quickly adapt to varying loads, preventing over- or under-utilization. Smart sensors continuously monitor the motors performance and environmental conditions, making adjustments on the fly. Whether it's adjusting to changing operational loads or optimizing for speed, these systems make the difference. In real-world applications, this means smoother operation, reduced energy consumption, and improved overall performance.

Real-World Success

Case studies from various industries highlight the transformative impact of variable displacement motors. In automotive applications, these motors have led to significant fuel efficiency improvements, reducing emissions and lowering operational costs. For instance, in electric vehicles, variable displacement motors enable more efficient energy management, extending battery life and enhancing overall performance.

In manufacturing, variable displacement motors have cut down on maintenance intervals, enhancing productivity. Companies like General Motors and Airbus have successfully implemented these motors in their production lines, resulting in reduced downtime and improved product quality. These examples show how these motors are not just theoretical concepts but practical solutions making a real impact.

Innovation on the Horizon

Looking ahead, the future of variable displacement motors is bright, with emerging technologies like IoT, AI, and nanotechnology on the horizon. Imagine motors that can self-diagnose, optimize performance, and adapt to their environment. These innovations could revolutionize industries, making motors smarter and more capable than ever before.

For example, with the integration of AI, variable displacement motors could predict and optimize their performance based on past patterns and real-time data. IoT sensors could continuously monitor the motor's health and performance, sending alerts and recommendations for maintenance or adjustments. Nanotechnology could enable more precise control and higher efficiency at the molecular level.

Future Possibilities

As these innovations unfold, the potential applications of variable displacement motors are vast. In construction machinery, these motors could enable smoother operation and better control over heavy loads, reducing stress on both the machine and the operator. In renewable energy, they could enhance the efficiency of wind turbines and solar panels, optimizing energy capture and storage.

Moreover, in healthcare, these motors could drive more precise medical devices, such as robotic arms and imaging equipment, leading to improved treatment and diagnostics. The versatility of variable displacement motors is only just beginning to be fully realized.

The Evolution Continues

Variable displacement motors are at the forefront of innovation, driving the next evolution in machinery. From their basic principles to advanced control systems, these motors are proving to be a versatile solution for a wide range of applications. As they continue to evolve, they'll play an increasingly vital role in shaping the future of technology and industry.

In conclusion, variable displacement motors are more than just a trendthey are a testament to human ingenuity and the endless quest for improvement. As technology continues to evolve, these motors will continue to transform the way we think about machinery, offering efficiency, adaptability, and innovation at scale. The future is bright, and the role of variable displacement motors is only just beginning.

ADD:No. 2 Tianchen Road, Yucheng High-tech Zone, Shandong

Copyright © www.highlandhydrostatic.com | Sitemap | Privacy Policy